A couple of years ago, I was completely new to electronics and never soldered a thing in my life. Fast forward to the previous week, I was soldering the 5th generation prototypes of the Ultimate Hacking Keyboard. It's been quite a journey and although I am by no means perfect at this stuff, upon reflecting on it I realized that I was able to push my PCB assembly productivity to the next level several times in a row, so let me show you what I learned.

Given that you asked for panels from the fab everything starts with depanelization. Even though this is a no brainer and doesn't require any skills or equipment other than a flash cutter, I decided to show it because I'm sure a lot of people have never seen it in action.

Next up, PCB assembly follows, so it's time to heat up the soldering iron.

Some words of advice:

Often times, it comes very handy to salvage SMD parts from previous prototypes which can be hard to desolder but with Chip Quik it's so much easier. On the video below it takes me 21 seconds to desolder a TSSOP 20 after starting to heat up the Chip Quik with my soldering iron.

Reusing PTH parts is usually much simpler but it can still be a pain. A desoldering station to the rescue! I purchased my ZD-985 desoldering station for about $100, probably the best bang for the bucks ever.

I'm pretty sure that I missed a lot of things but this is a very broad topic and I mostly wanted to give a glimpse into the world of PCB hand assembly. You're welcome to correct me, add suggestions and ask questions!

Up until this point I was the only one testing the UHK and using it as my daily driver which makes me feel all warm and fuzzy but also somewhat worried. As the lead developer of the project I'm hopelessly biased and rather clueless regarding how other folks would use it.

A while ago András and I were attending to Forbes Flow where we managed to show our beloved keyboard to Ádám Somlai-Fischer, cofounder & principal artist of Prezi. Prezi is considered to be the most successful Hungarian startup of all times so let me just say that this is a big deal for us. Thankfully, Ádám found our project quite interesting and generously offered his help. We asked for testers and we ended up getting contacted by them pretty soon.

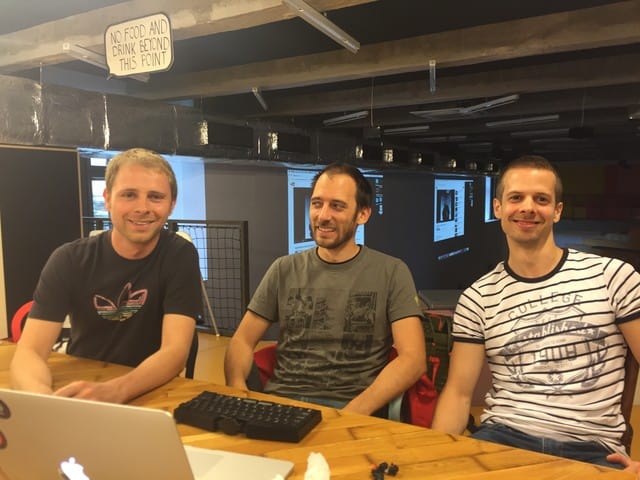

Today was a truly remarkable day because it hallmarks the delivery of our two, recently built, 5th generation prototypes to the chosen six, namely:

[fusion_builder_container hundred_percent="yes" overflow="visible"][fusion_builder_row][fusion_builder_column type="1_1" background_position="left top" background_color="" border_size="" border_color="" border_style="solid" spacing="yes" background_image="" background_repeat="no-repeat" padding="" margin_top="0px" margin_bottom="0px" class="" id="" animation_type="" animation_speed="0.3" animation_direction="left" hide_on_mobile="no" center_content="no" min_height="none"]

[/fusion_builder_column][fusion_builder_column type="1_1" background_position="left top" background_color="" border_size="" border_color="" border_style="solid" spacing="yes" background_image="" background_repeat="no-repeat" padding="" margin_top="0px" margin_bottom="0px" class="" id="" animation_type="" animation_speed="0.3" animation_direction="left" hide_on_mobile="no" center_content="no" min_height="none"]

[/fusion_builder_column][fusion_builder_column type="1_1" background_position="left top" background_color="" border_size="" border_color="" border_style="solid" spacing="yes" background_image="" background_repeat="no-repeat" padding="" margin_top="0px" margin_bottom="0px" class="" id="" animation_type="" animation_speed="0.3" animation_direction="left" hide_on_mobile="no" center_content="no" min_height="none"]

Apparently, we forgot to take pictures of Dávid and Vilmos so shame on us! Also, Kálmán couldn't make it but we hope that we'll be able to meet him in person eventually.

Thank you very much Prezi, Ádám, and the chosen six for your help! We already learned a ton of stuff from you guys and this is only getting better as you start to use the prototypes during your daily work. Fear not, we're here to hold your hands!

Last but not least, special thanks go to Ákos Tolnai, our strategic consultant from Ability Matrix. He was with us all the time at Prezi HQ providing invaluable insights that are critical to onboard future users as gracefully as possible.[/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

We at Ultimate Gadget Laboratories are unusually repair-conscious, especially compared to our throw-away culture. Most consumers are used to throw away gadgets when they break without second thinking. It's not only the fault of people because they're conditioned this way. Such an event of product failure is seen by the vast majority of corporations as the golden opportunity to extract even more money out of us, not only at expense of our pockets but the expense of our environment. But it doesn't stop here. Nowadays, companies are proactively trying to disable customers in every way possible repair-wise to increase their profits.

iFixit is at the forefront of progressing the state of repair. They provide a platform to publish tear-down guides so that one can repair any device based on these guides. Their manifesto speaks their values cleaner than I ever could and they also recently founded the Digital Right to Repair Coalition to fight for our right to repair.

Recently, I put together a document to let them know about our ways to make the UHK as repairable as possible. Apparently, they liked our concepts so much that they ended up making a post about us in their blog.

[fusion_builder_container hundred_percent="yes" overflow="visible"][fusion_builder_row][fusion_builder_column type="1_1" background_position="left top" background_color="" border_size="" border_color="" border_style="solid" spacing="yes" background_image="" background_repeat="no-repeat" padding="" margin_top="0px" margin_bottom="0px" class="" id="" animation_type="" animation_speed="0.3" animation_direction="left" hide_on_mobile="no" center_content="no" min_height="none"]

Thank you very much for the opportunity and especially for improving the state of repair, iFixit. We salute you![/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

Over the last weekend András and I were having a meeting to test whether our latest and greatest 5th generation prototype really fits together as expected. We've made a couple of improvements to this version, the most significant being the stainless steel inserts. Even though this might not seem like such a big deal to the outsider, in reality András had to make a huge number of changes to the CAD model to make this happen.

As always, a picture says more than a thousand words so let us show you the real deal.

Everything fit together very nicely apart from the 1.5mm thick stainless steel plates which were really 1.3mm thick due to the fault of the company that we entrusted. We're gonna have the steel plates of the correct thickness eventually and we'll assemble some prototypes using those.

It's always fun for me to see people experience our beloved keyboard and realize how it is familiar and yet different in a cool way. Lately, I've been to a Toptal meeting, followed by JSConf 2015 Budapest. In my true style, a prototype was in my backpack waiting to be seen by people. Naturally, some pictures were shot.

Even more recently, András and I were attending to a meetup at Ustream Hungary and the organizers have asked me to give a talk about the UHK in quite an unexpected fashion. I used our website as a presentation medium and got 5 minutes but the attendees asked so many questions that it ended up being about 20 minutes and people still couldn't get enough after the talk! It was a great experience for everyone involved.

Some of the things I learned along the way:

Yesterday András and I were attending to the opening of the 3D printing showroom of Varinex Zrt. who is the largest 3D printing company of Hungary. We were pleasantly surprised to see that one of the printers, namely a venerable Objet Connex 500 was printing 3 LED displays of our prototypes. Watching these printers in action is always very interesting so here's a short video for your viewing pleasure.

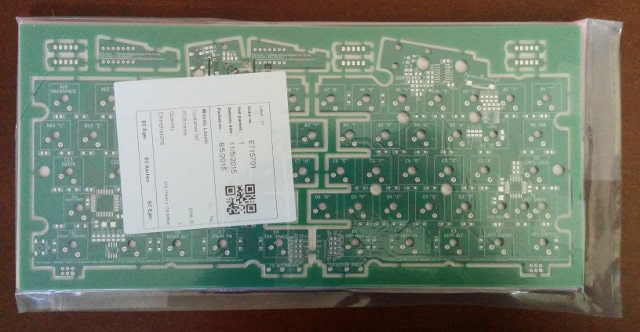

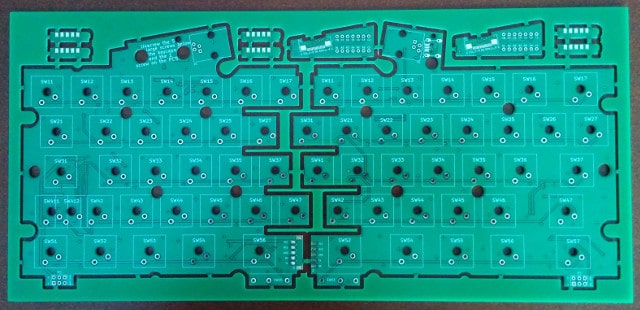

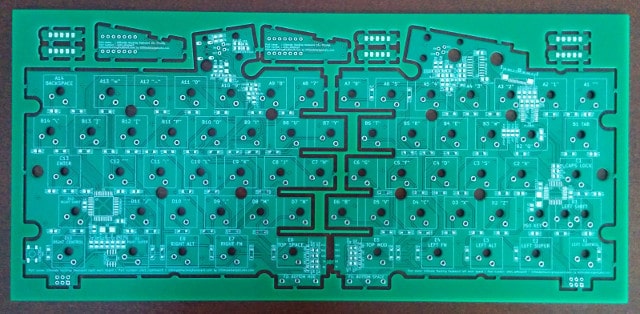

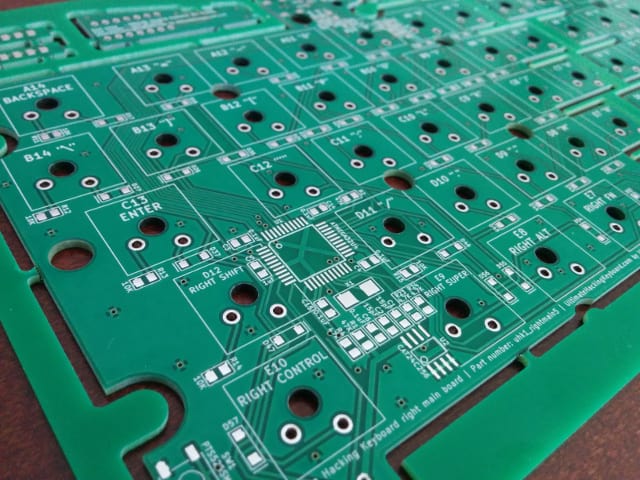

We're glad to announce that we've just received our 5th generation PCB! Compared to the previous version it's compatible with the ISO layout. Its contour is also a lot more complex to make place for the stainless steel inserts of the back side. Last but not least, the silkscreen became a lot more helpful, clearly showing the values of the various components, making assembly a lot easier.

[fusion_builder_container hundred_percent="yes" overflow="visible"][fusion_builder_row][fusion_builder_column type="1_1" background_position="left top" background_color="" border_size="" border_color="" border_style="solid" spacing="yes" background_image="" background_repeat="no-repeat" padding="" margin_top="0px" margin_bottom="0px" class="" id="" animation_type="" animation_speed="0.3" animation_direction="left" hide_on_mobile="no" center_content="no" min_height="none"]

[/fusion_builder_column][fusion_builder_column type="1_1" background_position="left top" background_color="" border_size="" border_color="" border_style="solid" spacing="yes" background_image="" background_repeat="no-repeat" padding="" margin_top="0px" margin_bottom="0px" class="" id="" animation_type="" animation_speed="0.3" animation_direction="left" hide_on_mobile="no" center_content="no" min_height="none"]

[/fusion_builder_column][fusion_builder_column type="1_1" background_position="left top" background_color="" border_size="" border_color="" border_style="solid" spacing="yes" background_image="" background_repeat="no-repeat" padding="" margin_top="0px" margin_bottom="0px" class="" id="" animation_type="" animation_speed="0.3" animation_direction="left" hide_on_mobile="no" center_content="no" min_height="none"]

[/fusion_builder_column][fusion_builder_column type="1_1" background_position="left top" background_color="" border_size="" border_color="" border_style="solid" spacing="yes" background_image="" background_repeat="no-repeat" padding="" margin_top="0px" margin_bottom="0px" class="" id="" animation_type="" animation_speed="0.3" animation_direction="left" hide_on_mobile="no" center_content="no" min_height="none"]

Redesigning the PCB always involves a ton of work and at this point it's more than mature so we don't plan to reiterate any more before the campaign.

Wanna see a bunch of high resolution pictures of the PCB? Head over the Google Plus album![/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

From time to time we get emails from you asking about the various options that you will able to choose from. In order to answer your questions properly we've added a new section to our site titled Make Your Choice. You're welcome to check it out to see the details for yourself.

Recording the audio samples for the 5 switch types was an especially time-consuming part of creating this section. As usual, we were serious about the details and quality so much so that I've asked my buddy Dömötör Gyimesi, founder and leader of Dreamgrave to help record these samples in their rehearsal room.

[fusion_builder_container hundred_percent="yes" overflow="visible"][fusion_builder_row][fusion_builder_column type="1_1" background_position="left top" background_color="" border_size="" border_color="" border_style="solid" spacing="yes" background_image="" background_repeat="no-repeat" padding="" margin_top="0px" margin_bottom="0px" class="" id="" animation_type="" animation_speed="0.3" animation_direction="left" hide_on_mobile="no" center_content="no" min_height="none"]

To make matters even more complex the continuous typing recording was created by me typing "ultimatehackingkeyboard" using every one of the 5 switch types. In practice, this was done by swapping the relevant 17 switches 4 times and rerecording the samples every time. Unlike all the other switches of this prototype these were not soldered in in order for them to be easily swappable. Still, the metal plate is quite tight and a signficiant amount of force had to be exerted in order to pop out the switches. Dömi was patient enough to wait for us so mad props to him!

[/fusion_builder_column][fusion_builder_column type="1_1" background_position="left top" background_color="" border_size="" border_color="" border_style="solid" spacing="yes" background_image="" background_repeat="no-repeat" padding="" margin_top="0px" margin_bottom="0px" class="" id="" animation_type="" animation_speed="0.3" animation_direction="left" hide_on_mobile="no" center_content="no" min_height="none"]

As for the gory technical details, an AT4040 cardioid condenser microphone was used for the recording with a Focusrite Scarlet 2i2 USB sound card along with the Cubase 7. Dömi hand-picked the best parts of the samples. No normalization was done on the samples to preserve their qualities as much as possible.

Let me take the opportunity to thank Dreamgrave for their help! Without them the recordings couldn't have been nearly as professional as they are. Be sure to check out Dreamgrave on Bandcamp, and listen to their sweet tunes![/fusion_builder_column][/fusion_builder_row][/fusion_builder_container]

We're in the process of finalizing our 5th generation prototype and thrilled about a new feature: threaded inserts! According to our knowledge this makes the Ultimate Hacking Keyboard the first keyboard ever that is mountable to external objects. "What external objects?" - you may ask. Think about things like a tilt stand, a kiosk or the arms of a chair. As usual, we have some pictures to show you the gory details.

It's easy to spot the 4 threaded inserts per keyboard half:

Same deal with the bottom part of the keyboard halves removed:

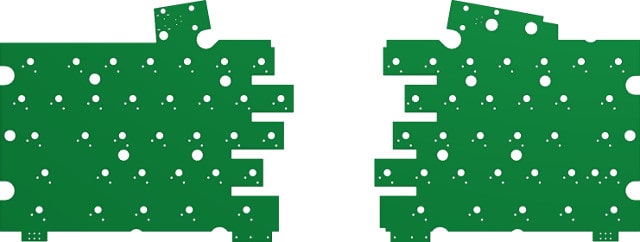

This makes the shape of the PCBs crazier than ever before:

We're super excited about this feature and the possibilities it'll bring. We expect the 5th generation prototype to be the last one before the campaign because we have to kickstart this project eventually. Regardless, we'll keep you posted so let's stay in touch!

Good news, everyone! After so many of you have expressed your desire for an ISO version, we finally decided to make it along with the ANSI version.

As for the Enter key, we will only provide bar-shaped Enter which might beg for some explanation.

The main reason is that bar-shaped Enter is more ergonomical. This layout also allows us to make the rightmost UHK keys shorter by half unit than on most keyboards, which makes the UHK more compact, and the keyboard halves more symmetric.

According to our experience, it's very easy to get used used to the bar-shaped Enter key. You can even swap the functionality of the bar-shaped Enter key and the "\" key above it on your UHK, making the "\" key send Enter.

Feel free to read why the bar-shaped Enter key is more ergonomical.